Why Choose a Company That Follows OEM Repair Guidelines

Many businesses rely heavily on special equipment that is essential to the process of delivering results. For a machine to deliver a consistent final product, it needs to follow certain rules and regulations that ensure it can keep up with expectations.

When there is a problem with a machine, it can sometimes be difficult to know what is wrong, but with constant maintenance and the help of professionals, this becomes easier. Companies that follow OEM repair regulations have higher standards and more accurate processes that greatly improve and expand your business.

What Is OEM?

OEM stands for original equipment manufacturer, which means that the company in charge of repairing your machinery will utilize parts from the original manufacturer. Professionals will ensure your heavy-duty equipment keeps delivering on the expected processes, which is especially crucial when your machine is essential to your business.

Complying with repair guidelines from manufacturers will ensure your equipment gets the right attention and pieces. Some machines seem similar but have assembling specifications that make a big difference in the overall repair process.

Consistent Results and Delivery

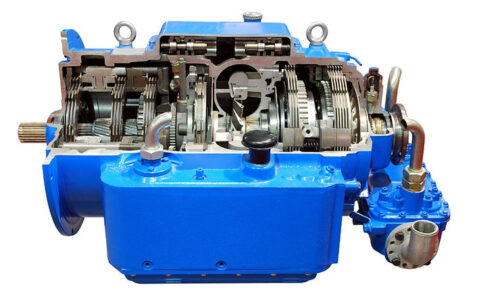

Machines require the use of many different pieces, and every piece has a specific task that will deliver a part of a process for consistent results. Replacing parts that are not from the original manufacturer could damage an operation with time. Some features are essential to a machine for certain reasons; replacing a damaged part with a different brand will not deliver the same results.

To obtain consistent results, you need the help of a professional industrial machine repair shop to attack the problem. Repair guidelines and knowledge are essential when dealing with expensive and large machines; every detail matters and every piece is necessary.

Damage Repair and Procedures

A company that follows OEM repair guidelines will have the right knowledge on how to deal with certain situations. There are different parts that could stop working for different reasons, and finding the source is essential to eradicating the problem. Replacing and fixing parts of a machine also typically involves scheduling an inspection

The process of repairing certain damages must follow specific guidelines. Every change requires a new balance and calibration; replacing a part is a whole process that requires the help of professionals to ensure good procedures and results.

24/7 Emergency Service: (770) 757-3530

24/7 Emergency Service: (770) 757-3530

23505 Views

23505 Views  0

0