5 Main Causes of Mining Equipment Failure

Mining operations play an important role in extracting valuable resources from the earth’s crust for multiple reasons. The efficiency and productivity of these operations heavily rely on the durability and functionality of mining equipment, which is why it must remain in optimal condition.

Equipment failure can lead to costly disruptions, production delays, and significant financial losses. Understanding the main causes of mining equipment failure allows companies to develop effective maintenance strategies and ensure uninterrupted operations.

Fatigue and Overloading

Mining equipment can suffer intense stress and fatigue due to prolonged usage and heavy workloads. Overloading equipment beyond its capacity can significantly increase the risk of failure. Fatigue failure can happen when repetitive stress cycles weaken the structural integrity of components over time, leading to cracks, fractures, and eventual failure.

Environmental Factors

The mining industry operates in diverse regions, exposing equipment to environmental challenges. Extreme temperatures, humidity, dust, and corrosive substances can damage equipment performance and integrity. Protective measures like regular cleaning, proper storage, and utilizing specialized coatings can help minimize the effects of environmental factors on mining equipment.

Lack of Proper Maintenance

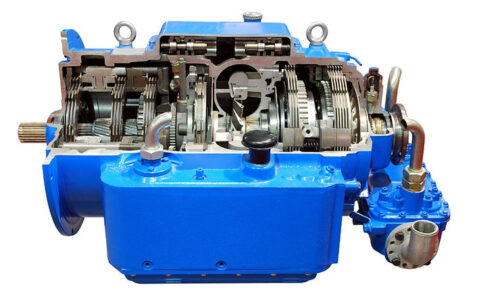

Mining equipment like draglines, shovels, and crushers operate under extreme conditions, suffering continuous exposure to dust, vibrations, extreme temperatures, and corrosive substances. Without proper care, these harsh operating conditions can accelerate the wear and tear of critical components, leading to unexpected failures. Dragline maintenance is important, which includes routine inspections, lubrication, cleaning, and component replacements when needed.

Inadequate Training

Human error from inadequate training or experience is another common cause of mining equipment failure. Operating complex machinery requires skilled and knowledgeable operators who understand the equipment’s capabilities, limitations, and proper usage procedures. Errors like improper operation, incorrect maintenance practices, or failure to identify warning signs can negatively affect equipment performance.

Manufacturing Deficiencies

Poorly designed or inadequate equipment that does not meet the demands of mining operations could lead to premature failure. Weak welds, poor material selection, and improper sizing of components can compromise equipment integrity and performance. Mining companies must prioritize equipment selection from reputable manufacturers known for their reliable designs and performance that adhere to industry standards.

Mining equipment failure poses significant challenges to the mining industry, impacting productivity, safety, and profitability. By understanding the main causes of equipment failure, mining companies can develop proactive maintenance strategies, invest in proper training, and make informed decisions when selecting equipment replacements.

24/7 Emergency Service: (770) 757-3530

24/7 Emergency Service: (770) 757-3530

23317 Views

23317 Views  0

0