Signs Your Mining Equipment Needs Repair

Machines that work in rough environments with heavy materials on the exterior need constant maintenance to ensure proper work and development. Different machines require certain maintenance specifications depending on their job type.

These signs your mining equipment needs repair are easy to spot and will prevent machine failure that could hold back your production. Constant maintenance after every use and knowing what to look for will optimize the way you manage and handle heavy-duty machines.

Check Liquid Levels

Every machine requires different liquids to keep the moving parts from damaging themselves or getting stuck. Just like cars need an oil change, every machine, especially heavy-duty ones, will wear down quicker if you don’t perform the proper maintenance.

With technology, newer machines alert you when something is not working or when the liquid levels are low. Because of the machine’s nature, you need to check for possible leaks constantly, punctured hoses, or even if the machine gets too hot when it’s in use.

Too Much Vibration

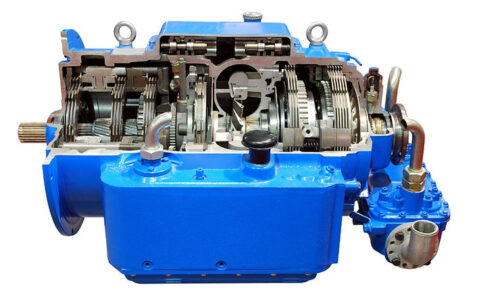

A problem with calibration and loose parts will cause your equipment to vibrate constantly and sometimes violently; this clearly shows that it needs repair. Some parts wear out more quickly than others, especially those with materials that are not as strong as iron or steel.

An imbalance in weight could also make your equipment vibrate; when parts misalign, they cause weight to shift, and with the constant vibration, it happens even more. Regular maintenance will prevent your equipment from breaking down, especially the ones essential to your business. A dragline repair is the best option before replacing the machine, combined with scheduled maintenance.

Discoloration and Fractures

Discoloration and fractures are some of the clearest signs that your mining equipment needs repair quickly. Discoloration on the moving part that receives most of the shock and is constantly in contact with rocks and dirt means maintenance is necessary. Fractures could result in a piece breaking and delaying your production.

You need to check for these every day after using your machines to get an idea of when it would be proper to get repairs. Ideally, you need to schedule maintenance every six months, but it also depends on your equipment’s usage and appearance.

You need professionals to help you with mining equipment repairs because large machines require attention to detail. Having a professional perform repairs will reduce the wait time since they can quickly locate the exact problem. Enjoy the benefits of a job well done on time and focus on what really matters.

24/7 Emergency Service: (770) 757-3530

24/7 Emergency Service: (770) 757-3530

2981 Views

2981 Views  0

0