Ways Dragline Maintenance Can Extend the Life of the Machine

Heavy-duty machinery and large equipment that works with heavy materials like rocks and excavation processes require more attention. Safety practices and proper use of the elements are essential to delivering consistent and reliable results.

Any machine constantly working under tough conditions during long periods will need constant monitoring to prevent breakdowns. Dragline maintenance will extend the machine’s life with practices that greatly benefit your business.

Keep In Functional

The environment in which draglines work makes it challenging to maintain consistency in daily deliveries that will keep your business functional. Situations like making up for lost time or increasing production will greatly benefit from constant dragline maintenance and cleanings.

Heavy-duty machines can resist tough environments, and paying attention to the smallest components, like bolts, locks, and lubrication will make a positive difference. Keeping a machine functional is essential for any business, and the equipment that does most of the work should be the main focus.

Avoiding Wear Down

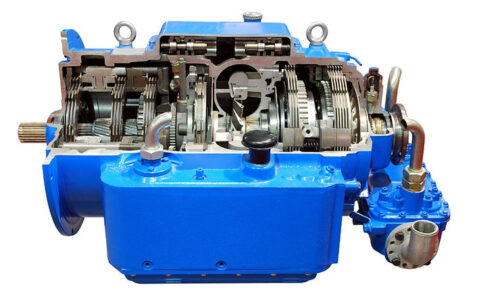

Moving parts create friction with each other, especially when those parts are metal. Good lubrication on those parts will prevent accidents from happening and will increase consistency in development. As a part of the constant maintenance, checking for worn-out pieces to fix and applying good lubrication will keep your machine optimized and lasting longer.

Fixing Any Problems

Maintenance will prevent problems from developing, and keeping a record of all the maintenance processes could locate problems quicker. Machines, like a dragline, need maintenance checks at least once a month because of the nature of the work it provides.

A machine usually warns when something is out of the ordinary, like overheating, vibrating intensely, or making strange noises. Fixing a problem before it affects production is one of the main focuses of maintenance checks. Dragline repair services offer the best solutions to any problem, including scheduled maintenance checks and best practices.

Keeping It Updated

Technology constantly updates and upgrades different features in machines that make a job simpler and more effective. Dragline maintenance will extend the machine’s life with new a more reliable parts that professionals will change and install for you.

Some machines built a specific way cannot get upgrades because it could compromise a process, but others have characteristics that make integrations easier. Replacing and switching some parts will make heavy-duty machinery work like new ones for longer.

24/7 Emergency Service: (770) 757-3530

24/7 Emergency Service: (770) 757-3530

2955 Views

2955 Views  0

0