Improving Mining Site Safety With Regular Equipment Repairs

Industries rely on machines to consistently perform a job and deliver good results, minimizing errors and downtime. Some practices are important to keep machines running smoothly and prevent accidents that could affect employees and the overall productivity of a business.

Regular equipment repairs can catch malfunctions before it’s too late to improve mining site safety. They will prevent the need to replace parts of a machine or the entire thing. Small daily routines are best for detecting damaged areas that need repair.

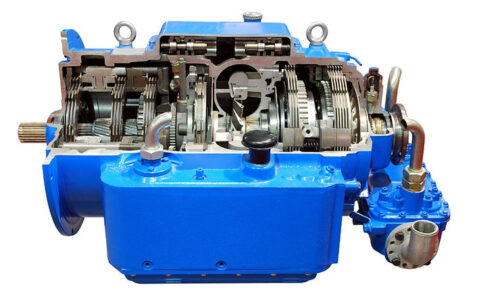

Scheduled Maintenance

Maintenance on heavy duty-machines like mining tools is essential because they come in close contact with strong materials. Scheduled maintenance routines for every piece of equipment will help you save time and money on repairs.

Detecting damaged equipment will give you the necessary information to act before having to shut down a machine. Dragline maintenance is essential, as your machines work nonstop with heavy and irregular objects. Optimal conditions will deliver good results.

Workers Performance

Equipment repair benefits the machine directly and allows the worker in charge to perform a better job and increase productivity. To improve mining site safety, it is essential that every machine works efficiently according to the knowledge and experience of the operator.

Regular equipment repairs mean enhanced consistency, which is important to deliver results in a high-intensity field. Repairing minor issues could have a great impact and cause less stress on the worker and machine.

Extended Lifespan

Some institutions check a company’s compliance with safety regulations to ensure they prioritize employee safety, involving fees and penalties. Constant monitoring, maintenance, and equipment repairs will extend the active lifespan of a machine and prevent replacements that could slow production. Professionals with the right experience and expertise will help your machines deliver better results and repair any unexpected issues.

Extending the lifespan of a machine that delivers consistent results will increase safety practices, especially in the mining industry. Some elements can damage a machine with time, like dust, sunlight, and weather; constant maintenance and safety practices will enhance consistency and safety.

24/7 Emergency Service: (770) 757-3530

24/7 Emergency Service: (770) 757-3530

2954 Views

2954 Views  0

0