Repairing vs. Replacing Dragline Machines and Equipment

Heavy-duty machines require constant maintenance and monitoring to avoid costly problems that could cause a drop in production and consistency levels. A business that relies heavily on machines must pay special attention to best practices to minimize errors that could cost the company time and money.

Mining equipment and machines that manage and deal with hard materials will inevitably have to adjust certain processes to continue functioning. You must consider various factors to determine the differences between repairing and replacing dragline machines and equipment and choose the best solutions.

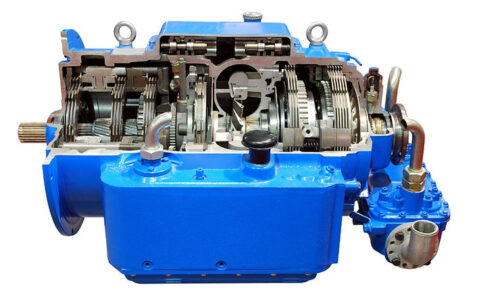

Repairing a Dragline Machine

Repairing a machine comes with various components you must inspect thoroughly before replacing the machine. The repairing process could be less costly and extend the machine’s warranty depending on how extensive the repairs must be.

Consistency in results depends on how well a machine performs and adapts to a process, which you can achieve with time and usage. Repairs vary depending on the problem, and this can be the best solution when parts and processes are available. A shovel repair is the most common because the equipment constantly moves and handles strong materials.

Replacing a Dragline Machine

Replacing a machine could get expensive, especially when it has unique characteristics to deliver specific results. A dragline machine costs around $50–100 million, which makes them large investments to keep a business running strong.

Completely replacing a machine could slow down a workflow, depending on how quickly the machine adapts to a process and the handlers. This option should be a last resort when the dragline machine or equipment is too old, has had many repairs, and doesn’t deliver consistent results.

How To Decide Between Repairing or Replacing

Every company relies on consistency, accurate time management, and smooth processes. You can achieve these things by replacing or repairing a machine, but you should consider other characteristics. If your machine keeps breaking down even after countless repairs, you must replace it.

Repairing or replacing dragline machines is sometimes necessary, especially with the hard work these machines must complete daily. Repairs will help you save time and money with the help of professionals to deliver good results. A replacement is necessary when the equipment has outdated parts, keeps breaking down, or can’t handle new attachments.

24/7 Emergency Service: (770) 757-3530

24/7 Emergency Service: (770) 757-3530

2956 Views

2956 Views  0

0