Reasons To Repair a Milling Machine Instead of Replacing It

Machines make processes more effective and predictable, meaning you always know what you will get from beginning to end. When something disrupts the workflow of a process, your production could slow down, and repairs could cost you valuable time.

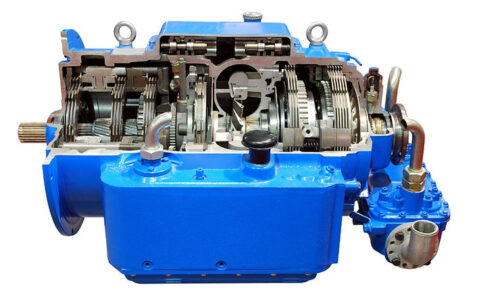

Your milling machine has a specific role in an industrial environment. It creates metal pieces for various purposes by precisely drilling lines and holes. It can also dispose of unused materials, making it a valuable asset. These reasons to repair a milling machine instead of replacing it will help you make an informed decision when you face a problem with the equipment.

Less Expensive

Repairing a machine instead of replacing it completely won’t exhaust your budget, and you won’t have to change your workflow. Industrial machines are expensive, and replacing your milling equipment could minimize your budget for other machines.

Preventive maintenance is the best way to keep a machine functional and reduce the need for repairs. Finding alternative ways to save money and time in your business will expand your reach and keep your heavy-duty equipment in good condition for years.

Extended Lifespan

A new machine’s lifespan could change depending on its use and the care it receives; you can extend your milling machine’s life with proper care. Once a machine reaches a certain age or hours of usage, its parts will begin wearing out.

Replacing the most important parts of a milling machine is necessary for extending the lifespan of the equipment. Raymond mill parts are some of the best options to keep a machine functional and apply upgrades.

Minimum Change

A change in the flow of a product or service will significantly impact the final result, especially after years of relying on the same equipment. Replacing a milling machine could slow down your workers and lead to processes taking extra time to balance out again.

Repairing a machine requires service providers to find the necessary parts. This is especially important with a milling machine because the wrong parts could negatively affect the entire system. Repairing a milling machine instead of replacing it will save you resources and keep your business thriving.

24/7 Emergency Service: (770) 757-3530

24/7 Emergency Service: (770) 757-3530

2952 Views

2952 Views  0

0