Warning Signs a Hydraulic Cylinder Needs Repair

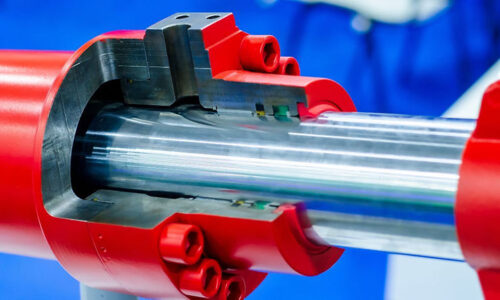

Hydraulic cylinders are essential for the proper functioning of industrial equipment and heavy machinery applications. They are necessary to convert fluid power into mechanical force, allowing the equipment to perform tasks efficiently.

Like any other mechanical component, hydraulic cylinders could suffer from wear and tear. To ensure the safety and productivity of your machinery, you must know how to recognize the warning signs that a hydraulic cylinder needs repair.

Reduced Lifting Capacity

Hydraulic cylinders are essential in heavy-duty machinery for lifting and pushing heavy loads. If there’s a gradual decrease in your equipment’s lifting capacity, it may be a sign of hydraulic cylinder problems. This reduction in performance could be due to internal wear, a damaged piston, or contaminated hydraulic fluid. A decline in lifting capacity could impact your business’s productivity and risk the worker’s safety.

Unusual Noises

A well-maintained hydraulic cylinder operates smoothly and quietly. If you begin to hear unusual noises, such as knocking, banging, or grinding during operation, it’s a warning sign that something’s wrong. These noises indicate issues like worn-out bearings, misalignment, or air trapped in the hydraulic system. Paying attention to these warnings can prevent further damage and extend the life of your hydraulic cylinder.

Slow or Jerky Movements

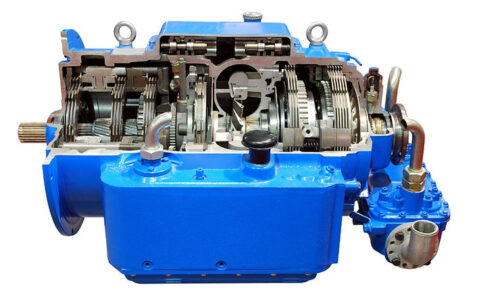

Hydraulic cylinders are popular for their precise and controlled movements. If you notice that your machinery’s movements are slow or jerky, there might be something obstructing the cylinder’s path. Disassembling the equipment is one of the best options to find the source of the problem and fix any damaged items. Working with professionals for a hydraulic cylinder rebuild will ensure your machine stays active longer.

Leaking Hydraulic Fluid

One of the most evident signs that your hydraulic cylinder needs repair is the presence of hydraulic fluid leaks. Hydraulic cylinders rely on pressurized fluid to function effectively. Leaks can happen from damaged seals, cracked tubing, or loose fittings. Ignoring these leaks can lead to reduced efficiency, increased energy consumption, and, sometimes, catastrophic failures.

Excessive Heat Generation

Hydraulic cylinders generate heat during operation, but excessive heat may reduce efficiency. If you feel that your hydraulic cylinder is running unusually hot, it may indicate problems within the system. High temperatures can accelerate wear and tear, leading to reduced cylinder life. Common causes of overheating include low fluid levels, dirty hydraulic fluid, or a malfunctioning cooling system.

Regular maintenance and inspections are essential to extending the life of your hydraulic cylinders and ensuring they continue to operate at their best. A well-maintained hydraulic cylinder will save you money in the long run and contribute to your equipment’s smooth and safe operation.

24/7 Emergency Service: (770) 757-3530

24/7 Emergency Service: (770) 757-3530

795 Views

795 Views  0

0