6 Important Maintenance Tips for Industrial Gearboxes

Industrial gearboxes are crucial in various industrial sectors, from manufacturing plants to power generation facilities. These mechanical systems are responsible for transmitting power and torque, enabling machinery to function efficiently and reliably.

Like any mechanical equipment, gearboxes require regular maintenance to ensure optimal performance and prevent costly breakdowns. These important maintenance tips for industrial gearboxes will offer valuable insights to keep machines ready and minimize unwanted downtime.

Maintain Proper Lubrication

Proper lubrication is essential for the smooth operation of industrial gearboxes and for expanding their life spans. Lubricants act as a protective barrier, minimizing friction and wear between the gear teeth to keep them in optimal condition. Pay attention to oil quality, cleanliness, and viscosity because contaminated or degraded lubricants can lead to increased wear, decreased efficiency, and even machine failure.

Monitor Vibration and Temperature

Monitoring vibration and temperature levels is a proactive approach to gearbox maintenance. High vibration levels can indicate misalignment, worn bearings, or gear damage, while high temperatures indicate inadequate lubrication, overloading, or faulty cooling systems. Regularly record and compare vibration and temperature readings to establish trends and take preventive action when necessary.

Inspect and Replace Worn Components

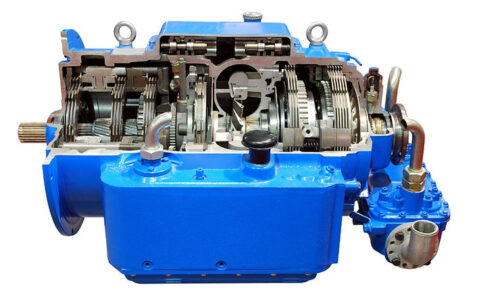

To detect any inconsistencies, perform inspections for signs of wear, pitting, corrosion, or damage in gears, shafts, bearings, and seals. A detailed examination can help detect early-stage problems and prevent deterioration before damaging the machine. Contact professionals to perform gearbox repairs and replace worn or damaged components promptly to avoid potential breakdowns or failures. Keep detailed records of component replacements, including dates, part numbers, and maintenance logs for future reference.

Align and Balance

Accurate alignment and balance are important maintenance tips for gearboxes to perform smoothly and stay active longer. Misalignment can cause uncontrollable vibration, noise, and early component failure. Balancing the rotating elements, such as shafts and pulleys, is equally important to reduce vibration and prevent unnecessary stress on the gearbox components.

Maintain Cleanliness

Maintaining cleanliness inside the gearbox is crucial for optimal performance and preventing performance issues from developing. Keep the external surfaces of the gearbox clean and free from debris that could potentially find its way into the system. Regularly inspect and clean breathers, filters, and seals to ensure their effectiveness in preventing contaminants from entering the gearbox.

Regular Maintenance and Documentation

You must have a well-defined maintenance schedule and keep meticulous records of all maintenance activities performed on the gearbox. Document key parameters such as oil change intervals, component replacements, alignment adjustments, and other important information. This documentation will be a valuable reference for future maintenance, troubleshooting, and analysis of the gearbox’s overall health.

24/7 Emergency Service: (770) 757-3530

24/7 Emergency Service: (770) 757-3530

3645 Views

3645 Views  0

0