5 Common Problems With Industrial Gearboxes

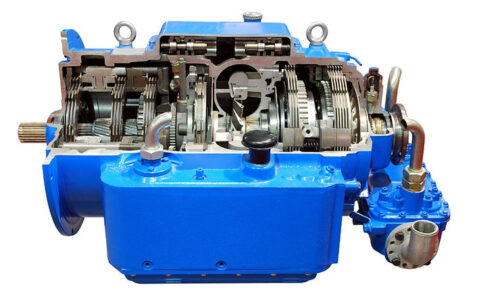

Industrial gearboxes are heavy-duty elements that allow big machines to work smoothly and consistently. Gearboxes are responsible for the performance of a machine and are essential to its ability to do a job correctly. Some common problems with industrial gearboxes come from not taking care of them and waiting too long between maintenance checks. It’s easy to recognize when something is wrong with these parts, but it’s also easy to keep them going with the proper maintenance.

Good Lubrication

This part of a machine works with speed and pressure, which means that parts are in constant motion. Lubrication is essential to avoid friction with these parts, which could damage them significantly. Gearboxes need special lubrication; some problems can arise from using inadequate lubricants that wear off quickly or cannot manage contamination from dust and debris.

Check Alignment

Like many machines that are under constant vibration and movement, gearboxes might see a shift in alignment and position over time. Regular checks and maintenance will ensure that this part of the machine stays put and ready. Misalignment might cause the engine to overheat, resulting in total failure. Schedule maintenance checks and keep thorough records to ensure functionality.

Corrosion Issues

Metal corrodes with exposure to natural elements such as wind, humidity, and extreme temperatures. Call gearbox repair services to assess the situation if you notice any problems caused by corrosion. These types of issues could lead to system failure and broken parts. These professionals may suggest repairing or replacing the box.

Usage Overload

Machines can work for long days with non-stop action, but this means that the parts will wear down quicker. To avoid common problems with industrial gearboxes, it’s essential to know the loads and capacities of a specific machine. Installing the wrong gear or overloading the correct one will harm the machine and cause the equipment to break down.

Constant Overheating

One clear sign that a gearbox is not working correctly is that it consistently overheats. When a machine has good lubrication, balance, and maintenance checks, this will not happen, but if the engine constantly reaches high levels of heat, that means there is an imbalance somewhere in the system. Monitor whether this happens during specific times of the day or if the system simply overheats at random.

Experiencing problems that could delay your work and possibly break down your machines is something to pay special attention to. If you know your gearbox is having any of these issues, contact us today and let the professionals take good care of your equipment.

24/7 Emergency Service: (770) 757-3530

24/7 Emergency Service: (770) 757-3530

2954 Views

2954 Views  0

0